Our Services

Our support and service:

Depositing and Printing hardware supplier:

- Depositing Pumps – For gelatine, chocolate, fondant or marshmallow lines.

- Nozzle plates – for a wide variety of pump types.

- Piston bars (pump bars) – for a wide variety of pump types.

- Mouldboards (printing boards) with metal moulds – for most moulding lines, supplied with mould strips or with individual moulds screwed to the board.

- Mouldboards (printing boards) with plaster moulds – for most moulding lines, ideal for short seasonal runs.

- Pump spare parts supply for a variety of pump types.

Pump Overhaul / Repairs support:

- Depositing Pumps – We repair all slide valve bar pumps.

Overhaul your existing worn pump to function as new, all work tested and guaranteed. Improve your depositing accuracy with PCE.

Other PCE services:

Pacific Confectionery Engineering also provide the following support:

- Design optimum mould layout configuration for starch-based products to achieve highest piece count output efficiency for all tray sizes ranging from laboratory trays 18” x 18” to standard trays 820 x 400mm to jumbo trays 1218 x 440mm.

- Determine ideal mould layout configuration for best print and minimum starch waste for all conditions.

- Design and produce moulds through NX software for manufacture.

- Design best belt layout configuration for Choc Chip products to achieve optimum output and efficiency for existing chocolate depositors for belt sizes from 460mm to 1500mm wide.

- Design and manufacture various depositing pumps.

- Determine optimum pump configuration for all products and applications.

- Onsite assistance for new and existing depositing lines where PCE depositing hardware is used.

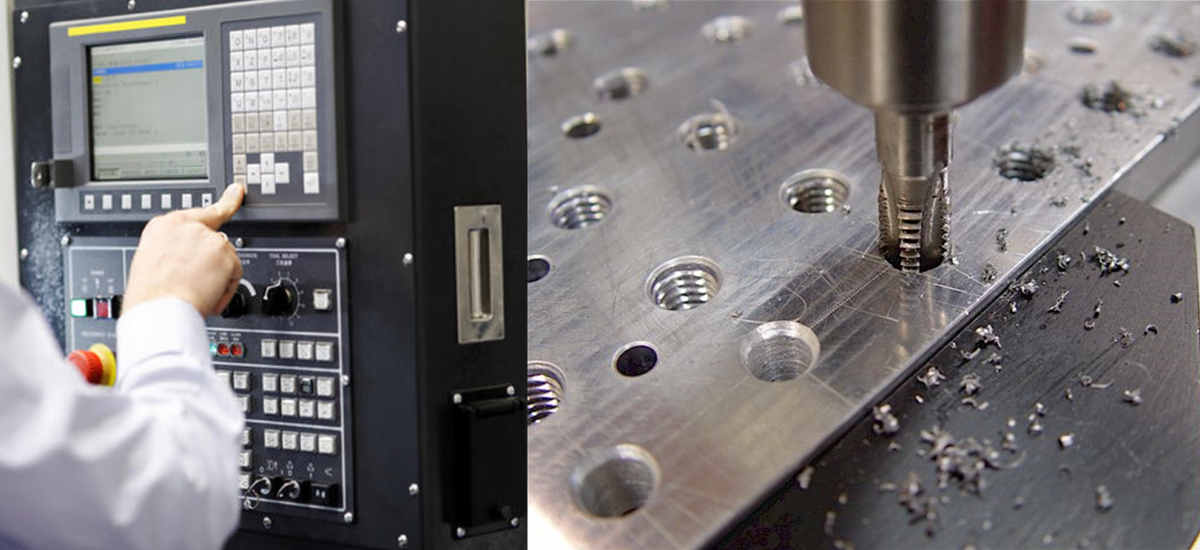

- Parts manufacturing with NX software that enables seamless manufacturing from digital part model to finish machined part ready for fitment and use.

- CNC programming.

- Reverse Engineering.

The success of your business is with PCE – The Starch Depositing Specialist!